Why EPDM is commonly use to make Car Weather stripping?

Once you talk about Car Weather stripping whether it is Windshield Seal, Door Weather Stripping Seal, Run Channel , Cowl Seal, Roof Rail Seal, Trunk Seal and other type of Moulding. EPDM will be the main material that commonly use to produce weatherstrip in every brand and model.

If we categorize the material for making weatherstrip that mentioned above, it can be categorize as 4 main materials. Each of it has the outstanding qualification as below :

- EPDM ( Ethylene-Propylene Diene Monomer ) has the outstanding feature and performance for UV protection, UV Ozone, weather & tear resistance, elasticity, long service lifetime more than 5 years. So, it is the perfect material for producing Windshield Seal ,Door Seal ,Sponge Seal and Weatherstrip. EPDM Weatherstripping at various points of heat exposure throughout the entire vehicle can maintain its temperature around -50 - 160°C (-122 - 320°F).

- NR ( Natural rubber) or the latex is extracted and processed from Hevea Brasiliensis (Rubber tree). In the past, as technology still old fashion and not modern as present, classic and vintage cars regularly use NR for producing Windshield Seal and Weatherstripping. However, this material has a unique tang smell, quickly deteriorate to UV Ozone, cracked frame in short period of time and also has a short service lifetime. As present, when advanced technology of synthetic rubber is modern. Therefore, NR is less using for making Windshield Seal and Weatherstripping. Nevertheless, NR is still be a good choice for producing Suspension Part and Bushing because of its outstanding in strength against pressure and friction force. NR can maintain its temperature of heat exposure around -55 - 100°C (-131 - 212°F).

-

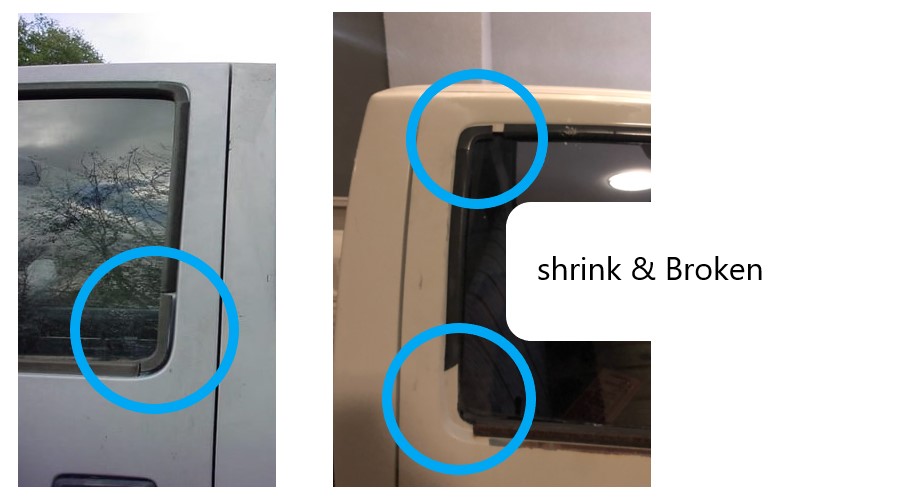

PVC ( Poly Vinyl Chloride) has the outstanding feature of smooth, brilliant appearance and easily of controlling shapes. However, its disadvantage is high shrinkage. So, the joint section of PVC will be tear off after being used by a period of time through the sunlight, rain and other weather condition.

PVC is still being used in present because the price is lower compare to EPDM. There are some parts such as Windshield Molding ,Belt Weather Stripping and Moulding still use PVC as the main material by having the wire or steel frame inside for protecting the shrinkage. PVC can maintain its temperature of heat exposure not over than 90°C (194°F).

- TPE ( Thermo plastic Elastomer) is constantly evolving by combining outstanding feature of PP Plastic and EPDM rubber which can be subdivided into many other types of material namely TPO and TPV. Both of these are often making production of Windshield Seal ,Door Seal and Weather Stripping. TPE can maintain its temperature of heat exposure around -30 - 140°C (-22 - 284°F).

However, any type of material for making the Windshield Seal ,Door Seal and Weather Stripping, if it is being used for more than 5 - 10 years, it is unable to resist the sunlight, rain and other weather condition while still being flexibility, good grip, waterproof and windproof like before or the new seal. These parts can be hardened, cracked, and deterioration which may caused water leak, drop and bad smell from outside to inside the cabin. So, it will be the time you should seek for the replacement for these seal.

Advance Auto Supply is an expert in Windshield Seal, Door Weather Stripping Seal and Trimming. We assort all the materials with the best criteria of quality first. We also can give an advice about Weatherstrip replacement part or Weatherstrip for car restoration. With over 40 years of experience in this field, we can develop all the Weatherstripping seal for many type of brand & model and can service the customer all over the world. For exploring our products please visit us as below :