Plastic Inner Fender Liners between Thermoforming Vacuum process and Injection process, which one is better?

Before everyone looking for the Fender Liner replacement, whether because of the original parts has been broken, lost without noticing or loud noise while driving because the part is loose or moving.

Firstly let’s start by getting to know Plastic Inner Fender Liners. Many of you might wonder that is there any reason or purpose why we need to install Plastic Inner Fender Liners or Plastic Under Engine Cover for all the car model?

For cars model older than 1980s, Steel Inner Fender Liner was used at that time because there was no Thermoplastic material technology. This technology was later developed and popularly produced Plastic Inner Fender Liners until now.

The main functions of Plastic Inner Fender Liners and Plastic Under Engine Cover are to

- Prevents rocks, dirt, mud or even dust from splashing into the engine compartment.

- Protect the car’s suspension system.

- Absorbs the sound of rubble and dirt from the outside entering into the cabin while driving.

- Extend the service lifetime of the vehicle body from the corrosion and rust.

Most of Plastic Inner Fender Liners and Plastic Under Engine Cover are usually made from HDPE Plastic ( High Density Polyethylene). This type of material has the unique resistant of crashing, heating, chemicals and flexibility.

It can also be easily molded. Therefore, HDPE is very popular for production in nowadays.

For moulding Plastic Inner Fender Liners and Plastic Under Engine Cover can be broadly classified into 2 processes :

- Thermoforming Vacuum

- Injection

Thermoforming Vacuum Process

The main process starts with mixing HDPE Plastic and other chemical ingredients which have a unique formula and the well-design materials to make sure that it will be durable and high flexibility.

Then it will be rolled into a plastic sheet as the desired size to be form in the next step.

After that, bring these sheets to be heated and keep the surface temperature approximately 140°C / 280°F for optimal forming. Then vacuum it on the mold, leave it cool, drill the holes, cut and trim the edge as the designed model vehicle.

The advantages of Thermoforming Vacuum process :

- The part is highly durable and flexible because the heat has been spread entire all the piece.

- The cost for product development process is affordable.

- Longer shelf life without cracking or breaking.

- Transportation or shipping is very convenient by folding, rolls and packed in small carton. How to delivery fender liners to customers ?

Disadvantages

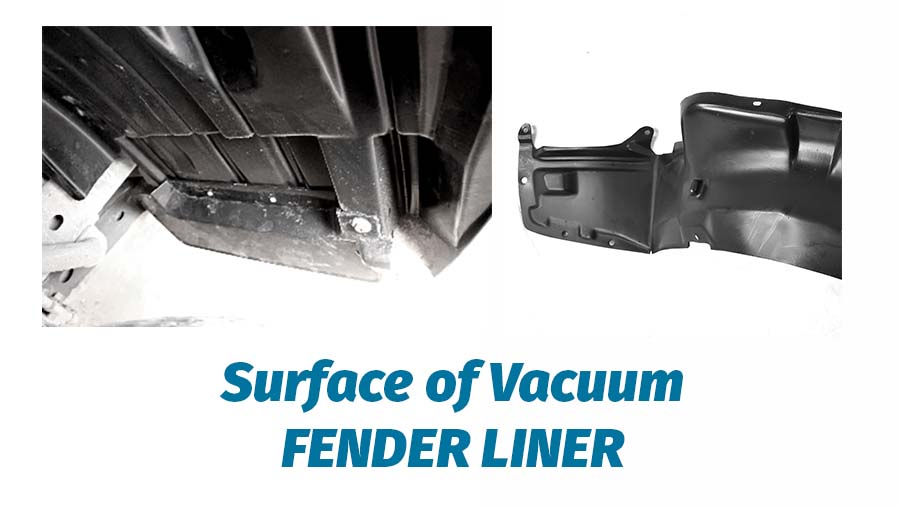

- The surface and texture of the parts are smooth and beautiful on the side that does not touch to the mold. On the other side, the surface of parts will be vary according to the mold quality. Advance Auto Supply using only the high quality of mold. Therefore, the surface and texture quality is still good and smooth.

- The price of the parts is higher than Injection process because it has many processes and steps to be done to get the finish parts.

Injection Process

It is the process that forming the finished parts by injecting plastic material molten by heat into a mold, and then cooling and solidifying it.

Advantages

- The surface and texture of the parts are smooth and beautiful for both side.

- The size and shape are highly accurate.

- The price of the parts is inexpensive compare with Vacuum process because there is only few steps to get the finish parts.

Disadvantages

- The parts can be easily broken or damaged because the durability is less than the Vacuum Process

- Shorter shelf life due to the parts can be broken or cracked by short period of time even it is not moving from the shelf.

- Transportation to different places is quite difficult and very expensive because parts can not be folded, rolled or packed into small carton. Checking how to delivery Fender Liners and shipping cost How to delivery fender liners to customers ?

Advance Auto Supply always emphasize on product quality, we do not compromise with lower quality or standard. Our priority is only provide the high quality products, durability, flexibility and long-lasting use to all customers. Therefore, all of our Plastic Inner Fender Liner and Plastic Under Engine Cover have been chosen to produce by Thermoforming Vacuum Process only.

On the issue of surface and texture of the parts, once these parts have been installed. It is hardly to notice the difference between Vacuum or Injection parts because one side of the surface is already attached to the car body.

Explore our plastic inner fender liner and plastic under engine cover here.

If any customer has any doubt or unsure about product selection whether it is the correct model or parts please see How to buy part online. or please do not hesitate to contact us or email .

Showing how flexible and strength of vacuum fender liner here.